CALCULATING

OVERSIZE THREADING ALLOWANCES

Many

people believe that to calculate the increase required for surface

coatings, one must add the actual thickness of the coating to

the component dimensions. This is not the case.

This assumption is fine in the case of plain bar, where the

physical increase is measurable in vertical and horizontal planes.

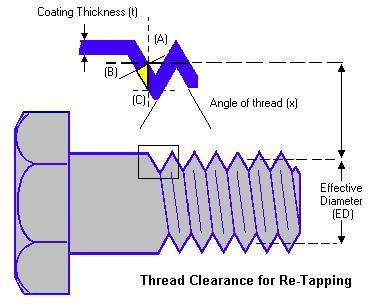

With threaded components the additional coating is applied to

the threads at an angle, hence the resulting increase upon the

"effective diameter" is greater than the increase

upon the plain shank in terms of the engagement with the nuts.

It

is necessary for Commercial Fasteners to be interchangeable

throughout the World, so manufacturers have adopted universal

standards to ensure dimensional compatibility.

Screw

thread measurement is based upon a theoretical dimension known

as the "Effective Diameter". Although there are still

many different thread forms in use today, this system is used

in virtually all instances. The Effective Diameter (ED) is a

measurement taken from an axis drawn horizontally, at approximately

half of the total thread height, to a mirror image position,

diametrically opposite (See figure). The same designation is

applied to both internal and external threads.

Manufacturing

standards have been created around this method based on the

"Nominal" or ideal dimension in each case, and are

based upon these standards, from which the allowance for oversize

tapping is derived.

In

most cases, the Male fastener is assumed to be manufatured to

nominal dimensions before coating applied. However, some manufacturers

choose to reduce the effective diameter of the bolts by "underscrewing"

the threads. With hot dip galvanising however, a re-tapping

operation is still necessary because the threads of the nuts

still tend to fill up when coated. Oversize tapping is the more

widely adopted solution as in this case the original integrity

of the male fastener is not compromised with a view to Tensile

Strength